This brief article explains the work flow procedure for site engineeers to execute steel sheet piling works. The procedure details various steps and checks that are recommended to be followed for such activities.

• Piling contractors must be requested to provide a written method statement as appropriate for the piling operations. Find out what induction training and information specific to a method statement is provided by immediate site supervisors to piling operatives.

• Note that cranes must be selected and used in accordance with CP3010 and with the Construction (Lifting Operations) Regulations 1998. A firm level base of adequate bearing value must be provided, or crane mats used.

• Check that cores of pendant/bridle ropes are not fractured.• Any crane used for raising or lowering operatives must be fitted with a dead man’s handle and the descent must be effectively controlled; the latter may be achieved by power lowering. Properly constructed man-carrying cages, which are unable to spin or tip, must be used. The cages should be regularly and carefully inspected.

• All lifting appliances and gear must carry appropriate certificates of test and examination, and must be adequate for the job, paying particular attention to the risk of damage to gear by sharp edges.

• All personnel working on piling operations must wear safety helmets (helmets appropriate for piling work are now available with retaining strap and smaller peaks). Ear and eye protection should be provided.

• Piling machine operators must be at least 18 years of age, trained, competent, medically fit and authorised by site management to operate the machine.

• When piling from a pontoon or adjacent to water, personnel must wear life jackets. Rescue equipment (e.g. a safety boat and lifebuoys with lifelines attached) must be kept ready for immediate use and enough operatives must know how to use it.

• When splitting bundles of sheet piles, use chocks. If large quantities of piles are handled, the use of purpose-made strops and grips is advised.

• Piles should not be stacked too high or in a cantilever position. Use spacers and chocks where necessary. Tubular piles should not be stacked more than four high and should be properly chocked.

• When lifting piles or piling hammers, use hand lines to control the load. Give due consideration to wind speed during the operation.

• Check the dimensions and alignment of clutches. If necessary perform trial clutching of piles. This is advisable for Z-shaped pile sections where the clutch is less positive than on trough sections (e.g. Larssen piles).

|

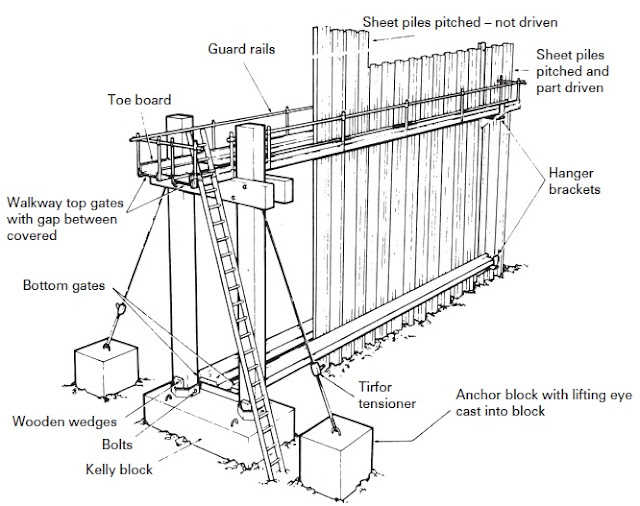

| Figure 1. Gate system using concrete bases (showing piling, the use of hanger brackets and the provision of a safety walkway). |

• Positioning (pitching) and driving sheet piling is usually done by using a temporary supporting structure (gate). This is made up of heavy steel or timber H-frames supporting horizontal-heavy H-beam guides. The H-frames can be supported on heavy steel spreaders or specially cast concrete blocks. Ensure an adequate foundation under these frames and bases to prevent subsidence and overturning during piling operations. This is particularly applicable during work in rivers, etc.

• If using concrete blocks ensure that they are suitably reinforced to withstand loads from lifting and shock loading. Vertical steel columns should have a good bottom fixing. Vertical timber should not be cast into the block but should be wedged and bolted. Where doubt exists over stability use guy lines or raking steel props.

• All horizontal gates with platforms over 2m high, or over any potentially dangerous areas, must be provided with adequate guardrails, toeboards and correct ladder access.

• Ladders must be secured and extend at least lm above staging.• If using a cantilever system, use a tie-back where possible, as well as kentledge to provide safe anchorage.

• When piling is progressing and temporary piles are used to support the gate system, use purpose-made brackets and bolt them to the piles. Any welding necessary should be carried out by competent welders.

• If shackle holes have to be burned in the pile, remove sharp burrs to prevent damage to shackle pins.

• Use quick-release shackles wherever possible:– the sheet pile must not be lifted vertically without first checking that the pin is properly engaged through the sheet

– do not use a pull rope less than 5mm diameter– the length of rope used must be less than the length of the pile, to prevent the extra rope snagging and pulling the release for the shackle

– secure the rope around the sheet pile to prevent snagging– if a special lifting eye is to be welded to the pile for angled pitching, the weld should have a factor of safety of at least 2.

• Pitch long sheet piles with a pile threader, following the manufacturer’s guidance for use. Where this is not possible, use a pile pitching cage. The cage is normally hung from an adjacent pile, the operatives wearing safety harnesses hooked to the adjacent pile before the crane hook is removed from the cage.

• When feeding sheet piles through the top and bottom gates, use wood blocks or a bent bar. Never use a straight pinch bar, as fingers can easily be trapped. Use a spacer block between the guides to keep the leading free clutch in its correct alignment.

• Where access and work is carried out from ladders:– Clutching: the ladder must be placed in the valley of a previously placed pile; the ladder must be footed and when at the top of the ladder both hands are required for clutching, a safety belt must be worn and secured to the pile using a manlock.

– Wedging: the ladder must be placed against the H-beam and footed wedges should be pre-placed on the beam. A 4 lb. lump hammer must be used as this can be swung with one hand but if two hands are required, a safety belt must be used with the lanyard wrapped around the H-beam or used with a manlock.

Note: At all times safety helmets and footware must be worn. When working at height the helmet should be secured with retaining strap.

• Changes in work method:– The work method must not be changed without consultation of the senior site representative responsible for the piling operation.

– If windy conditions (e.g. over 30 mph gusts) make the handling of the sheet piles difficult, stop work until the senior site representative responsible for the piling operation has been consulted and a safe method of continuing the work has been devised.